Iron ore

Overview

Ferro laterite, rich in iron and nickel, is a vital resource for producing alloys like nickel, cobalt, and iron. Swarna Aditya mines ferro laterite in Karnataka and Maharashtra, serving industrial sectors such as stainless steel and battery production.

Mining Operations

Exploration and Surveying

Conduct detailed geological surveys to locate and map ferro laterite deposits.

Utilize geophysical and geochemical methods to assess the quality and extent of the ore body.

Drilling and Sampling

Implement systematic drilling programs to extract core samples.

Analyze samples to determine mineral content and ore grade.

Feasibility Study

Conduct comprehensive feasibility studies to evaluate the economic viability of mining projects.

Assess environmental impacts and devise sustainable mining practices.

Site Development

Construct essential infrastructure such as roads, processing facilities, and worker accommodations.

Install advanced mining equipment and machinery.

Extraction

Employ open-pit mining techniques for ferro laterite extraction.

Utilize heavy machinery for drilling, blasting, and transporting ore.

Processing

Employ open-pit mining techniques for ferro laterite extraction.

Utilize heavy machinery for drilling, blasting, and transporting ore.

Processing

Hydrometallurgical Process

Leaching: Use acid or ammonia solutions to dissolve nickel and cobalt from the ore. Solvent Extraction: Separate metals from the leach solution. Electrowinning: Recover metals in pure form through electrolysis.

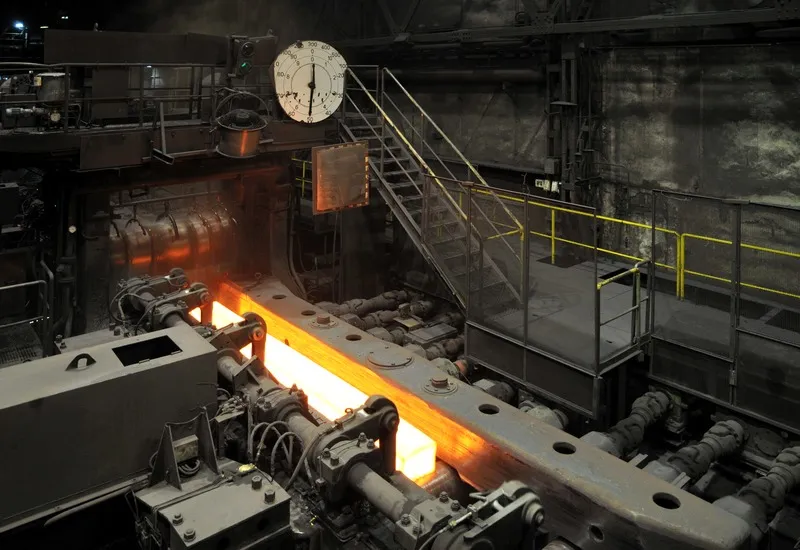

Pyrometallurgical Process

Smelting: Heat ore at high temperatures to produce a nickel-rich matte in a furnace. Converting: Further refine matte to separate nickel and cobalt. Refining: Purify extracted metals to achieve desired quality.

Usage of Ferro Laterite

Nickel Production

Essential for stainless steel manufacturing, electroplating, and battery production for electric vehicles.

Cobalt Production

Vital in high-performance alloys, superalloys, and rechargeable batteries, especially in smartphones and electric vehicles.

Iron Production

Used in various iron and steel-making processes, including cast iron and wrought iron production.

Environmental Management

Rehabilitation and Reclamation

Post-mining, restore land by planting native vegetation and rehabilitating natural habitats.

Water Management

Implement efficient systems to prevent contamination of local water sources. Treat mining process water before release into the environment.

Air Quality Control

Utilize dust suppression systems and monitor air quality to mitigate emissions from mining activities.

Economic Impact

Employment Opportunities

Create jobs for local communities and skilled professionals, fostering regional development.

Revenue Generation

Boost company revenue and support further investments through ferro laterite extraction and processing.

Infrastructure Development

Contribute to local infrastructure development, including roads, transport networks, and community facilities.

Conclusion

Swarna Aditya mining and production of ferro laterite play a pivotal role in supplying essential metals for industrial applications. Through sustainable practices, we meet global demand while fostering local economic growth and environmental responsibility.